Gyratory Swing Screen Quartz Sand Vibration Sifting Sieving Filter for Silica Powder

Basic Info

| Model NO. | FYBS-1536 |

| Type | Linear |

| Function | High Frequency Vibrating Screen |

| Transmission Structure | Eccentric Vibrating Screen |

| Usage | Mine Shaker |

| Works | Rotary Vane Shaker |

| Object | Ore |

| Shaft Number | Double |

| Running Track | Linear Vibrating Screen |

| Supporting Device | Rubber Spring |

| Warranty | 12 Months |

| Customized | Customized |

| Condition | New |

| After-sales Service | Online Support, Video Technical |

| Phase | 3 |

| Material | SUS 304/316 or Carbon Steel or as Customer Request |

| Power | 0.25-3(Kw) |

| Deck | 1-9 Decks |

| Certification | CE |

| Cleaning System | Ultrasonic System |

| Voltage | 380V/415V |

| Transport Package | No Packing |

| Specification | 1500*3500mm |

| Trademark | Sanyuantang |

| Origin | Xinxiang, Henan |

Packaging & Delivery

Package size per unit product 260.00cm * 230.00cm * 280.00cm Gross weight per unit product 5500.000kgProduct Description

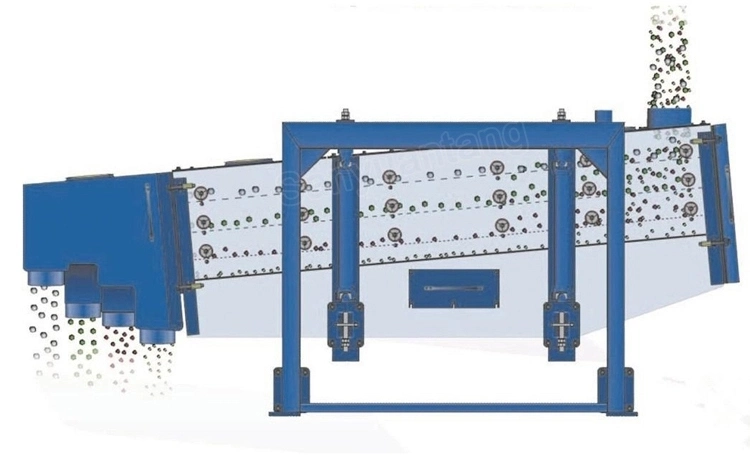

Gyratory Swing Screen Quartz Sand Vibration Sifting Sieving Filter for Silica PowderProduct Description

FYBS -1 Square swing screen is a high-efficiency screening equipment specially designed for high precision and large output. It is widely used in chemical, non-ferrous metals, food, quartz sand, abrasive and other industries.The screen mesh frame and the screen mesh installation method adopt a unique and innovative design, and the installation is very convenient.Usually 9-layer design,can be divided into 10 grades at one time,or 4 layers + 4 layers equivalent to 2 sets sieve machine, or 2 layers + 2 layers + 2 layers equivalent to 3 sets sieve machine or designed as 1 layer + 1layer + 1 layer + 1 layer + 1 layer is equivalent to 5 sets sieve machines.

Features

1,The grading ability is super strong, and the screening of 9th layer 10th grade or 11th layer 12th grade is completed once.

2,The fine screening area is super large, and the area of one sieve machine is about 50 square meters, and the production capacity is super strong.

3,Unique multi-layered design, multi-purpose machine.It is convenient to replace the screen mesh. 4,The sealing effect is very nice.

Technical Parameter

Model | Screen mesh size | Screening area (square meter) | Screen angle | Layers | Powder (kw) | Number of rotations | Screen box stroke (mm) |

| FYBS1536 | 1.5m×3.5m | 4.5-9 | 5-8 | 1-10 | 5.5 | 180-260 | 25-60 |

| FYBS2040 | 2.0m×4.0m | 8-9 | 5-8 | 1-10 | 7.5 | 180-260 | 25-60 |

Application of Square Swing Screen

Product ShowsWhy Choose Sanyuantang

1) International high quality certification product chain2) Manufacturer, more reasonable price3) Solid technical support and after-sales service4) Uphold the principle of "Customer Supreme"5) Exports to more than 20 countries and regions, good customers feedback6) One-stop service, customized exclusive project feasibility report.

Other Products

Our Services

All produts purchased in our company are guaranteed to keep in good repair for one year. If quality problems happen in guarantee period, our company will maintain for free.

a, Before sending the machine, we will test and adjust, so you can use directly when you get it.b, Operation video & instruction will be sent to clients, to help them use the machines better.

Additionally, our company provides technical support and fittings for life. After-sales service isn't restricted by time and we will solve your problems in time. If you are caught in some problems when using our products, welcome to contact us at any time.

a, Any problems occur while using, professional advice will be offered.

b, All kinds of frequently used parts are supplied all the year round.

c, 24 hours hot line/Whatsapp/Wechat

FAQ

Q: What are you mainly specilized in?

A: Our company is a professional manufacture of vibrating screen sifter equipments(like rotary vibrating screen,ultrasonic sieving machine,linear vibrating screen,test sieve machine,trumbler screem,drum screen,direct discharge screen,airflow sieving machine,450 filter machine and so on);conveying equipment (like screw conveyor,vertical bucket condeyor spiral elevator and so on);honey machine(honey processing machine,honey filling machine)Q:What's your after-sales services?

A: 24 hours service online,you can tell your trouble any time.

Q:What is the MOQ of our products?

A:Usually 1 set

Q:What is the payment terms?A. Usually use T/T,but Western Union is also available

Q:What's your delivery time?Ususlly 7-10 working days,if the order is large,the time should be longer

Q:What's the advantage compared to other suppliers?

A:We are a factory,We have business directly with our customers,there isn't any link between customers,so we can offer competitive price for you.

Buying Guides

The proper selection of the vibrating screen depends on the material, mesh size, output required, method of input etc:1. Name of material: _____2. Moisture:_____%3. Specific gravity:_____ [It means g/cm3 or kg/m3]4. Capacity:________kg/ hour5. Screen layers:_______ layers6. Screen mesh size:______ mm . ______ mm. ______ mm.______ mm.7. Voltage:______V, Frequency:______HZ, 3 phase8. SS304/316L stainless steel or Q235A carbon steel?Contact Us

Pls write down your inquiry below, and click "Send".We'll get back to you within 12 HOURS!Customer Question & Answer